CloudCam iQ for yellow iron, haul roads & jobsites.

Put cameras and tracking on the machines that move earth, rock and material—so you can see what’s happening on every job, in every pit and around every crew.

Mud, dust, blind spots & machines that can’t go down.

Your yellow iron lives in harsh environments, moves near people and utilities, and represents major capital. When something goes wrong, downtime and claims get expensive fast.

- Reduce incidents around people, utilities and property lines.

- Protect high-value iron from misuse, side jobs and theft.

- Answer “what happened?” with video and GPS—not guesswork.

Haul roads, pits & jobsites

One day can include plant roads, quarry entrances and tight urban jobs. You need visibility everywhere—not just on public highways.

Crews, subs & neighbors

Big iron moves inches from spotters, temp workers, utilities and property lines. Video and GPS history help you understand what really happened when something is struck.

Iron that must keep producing

Unmonitored machines are at risk of misuse, side jobs and theft. Cameras and trackers put you back in control of where assets are and how they’re used.

AI dashcams + rugged trackers for every piece of iron.

CloudCam iQ combines multi-angle cameras with trackers like Knight, Power, Power+ and Solar to cover haul units, loaders, excavators and remote assets in one platform.

- Standardize coverage across haul units, loaders, excavators and more.

- See production iron, support trucks and remote assets in one view.

- Optional temperature monitoring sensors where conditions or materials demand it.

Production units & support iron

- Multi-angle cameras for loading, hauling, dumping and backing.

- Knight & Warrior trackers for engine hours, location and run-time.

- Breadcrumb history to show where machines worked and when.

Yards, pits & remote assets

- Solar and low-power options for gear that sits remote between jobs.

- Geofences for pits, plants and laydown yards to flag unexpected moves.

- Single map for line-of-sight across all active and staged equipment.

Side, rear, dome and wireless cameras can be mixed as needed to cover blind corners, backing zones and swing paths around your iron.

From dispatch board to field, every move leaves a trace.

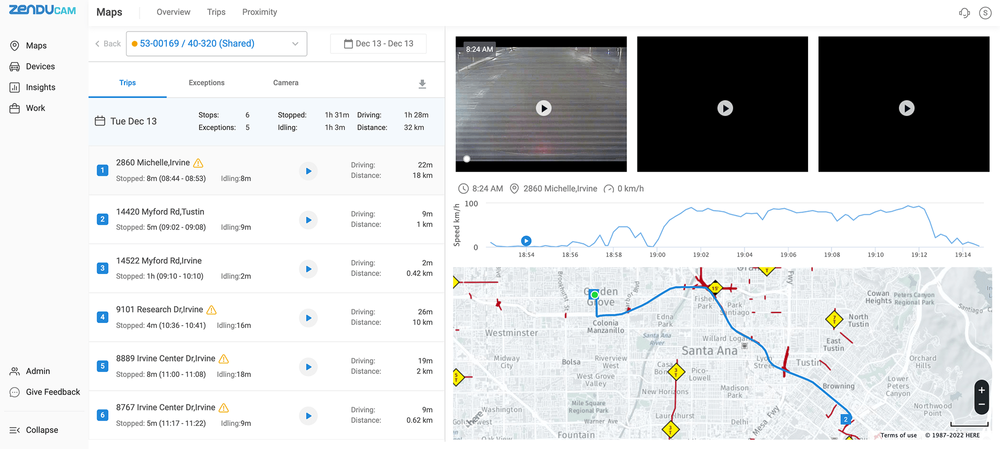

See live locations, movement history and events for heavy equipment on a single map. When a question comes in, you can answer it in seconds with facts.

- Know where every unit is and what it’s been doing.

- Reconstruct incidents and production issues in minutes.

- Spot underused iron and opportunities to right-size fleets.

Haul & site movement history

- Confirm machine paths through plants, pits and job entrances.

- Reconstruct production issues tied to haul cycles or dump queues.

- Match movement to time-stamped incidents and complaints.

Jobsite utilization & staging

- See which units actually worked vs. sat staged for days.

- Use engine hours to guide PM schedules and rental decisions.

- Spot iron that’s consistently under- or over-used across projects.

Where construction & heavy fleets lean on CloudCam iQ.

These are the situations that end up in claims files, project reviews and tough conversations with owners and GCs when evidence is missing.

- Turn “he said / she said” moments into clear footage.

- Improve safety talks with clips from your own jobsites.

- Support better rates and terms with stronger evidence.

Common issues we help you resolve

Combine side/rear views with GPS speed to understand how fast the unit was moving, how spotters were positioned, and what visibility looked like.

Time-align asset movement and camera angles with the moment a wall, fence, pole or line was hit to see whose machine was actually involved.

Geofences and hour rules flag machines that move outside allowed times so you can address problems before they lead to incidents.

AI dashcam video and telematics give your team and insurers a clear narrative of what happened seconds before impact.

How safety & operations teams use it

- Run post-incident reviews using real footage instead of guesswork.

- Build toolbox talks from near-miss clips on your own jobsites.

- Monitor speeding, harsh events and seatbelt use on high-risk moves.

- Track utilization and idle time to support right-sizing decisions.

- Provide owners and GCs with evidence when questions arise.

Many contractors first equip highest-risk jobs and critical iron, then extend coverage across the rest of the fleet as they see results.

Get a CloudCam iQ plan for your iron.

Share your mix of yellow iron, pits and jobsites. We’ll map out camera and tracker options, estimated pricing, and a rollout plan that fits your projects and schedule.

- Short discovery call focused on your jobs and equipment.

- Construction-specific demo with real workflows and examples.

- Clear pricing, including the $5 per unit monthly service program.

Service options that respect job schedules.

Once your cameras and trackers are installed, you can stay with the standard warranty or enroll units in the CloudCam iQ service program for extra protection.

- Unlimited warranty while enrolled at $5 per unit monthly.

- Plan support costs across projects instead of reacting to failures.

- Optional add-ons like temperature sensors supported where needed.

With service program

$5 per unit monthly

- Warranty and out-of-warranty repairs and replacements included.

- Unlimited warranty while enrolled in the program.

- Predictable support costs across projects and seasons.

Without service program

- Standard 3-year warranty on covered hardware only.

- Customer is responsible for labor (CloudCam iQ can provide labor separately).

- Out-of-warranty issues are not covered.

We’ll help you choose which equipment groups should enroll based on utilization, environment and age during your demo or planning call.

Construction & heavy equipment questions we hear.

Safety directors, equipment managers and project executives tend to ask a similar set of questions when they evaluate connected cameras and tracking.

- Understand hardware durability, rulesets and integrations.

- See how other contractors use CloudCam iQ day to day.

- Clarify rollout timing, fleet size and support options.

Will the hardware survive dust, vibration and weather?

Yes. We use commercial-grade cameras and trackers designed for harsh environments, with mounting and wiring practices tuned for construction and industrial use.

Can we separate on-road and off-road rules?

We can configure different alert thresholds and rulesets based on geofences, asset types or time-of-day, so jobsite behavior is treated differently than freeway driving.

Does this replace our maintenance or project systems?

No. CloudCam iQ complements your existing systems by adding video, GPS, engine data and history. Data can be exported or integrated where appropriate.

How does this help with insurance and claims?

Fleets use CloudCam iQ to provide clear evidence in claims, show active safety programs and support conversations about favorable rates or deductibles.

What fleet size do you support?

We work with everything from smaller regional contractors to larger multi-yard fleets. Many start with a focused pilot and grow from there.

Can we expand to other fleet types later?

Yes. The same camera and tracker families support waste, utility, municipal, delivery and other fleet verticals on one platform.

Ready to put eyes on every critical move on your jobs?

Share your mix of yellow iron and remote assets. We’ll build a construction-focused demo, outline hardware options, and walk through the $5 per unit monthly service program.

Book a Construction Fleet DemoPrefer to talk first? Call 732-327-4327 or email sales@cloudcamiq.com.