CloudCam iQ for refrigerated trucks, trailers & cargo.

Keep eyes on the road, the doors and the route history—while protecting temperature-sensitive loads with real-time visibility from dock to delivery.

One breakdown can wipe out a trailer—and a relationship.

In cold chain, it’s not just about getting there on time. It’s about getting there with product that stayed within spec the whole way—and being able to prove it to shippers, receivers and auditors.

- Protect high-value, temperature-sensitive loads from dock to dock.

- Show clear proof when customers or auditors ask “what happened?”

- Reduce full-load claims with faster investigations and fewer gray areas.

High value, short window

Perishable loads and strict temperature bands mean a single unresolved issue can turn into a full-load claim, disposal costs and strained customer relationships.

Documentation expectations

Food safety and pharma guidelines expect you to show how product was protected in transit— where you went, how long you stopped, and what happened around the cargo.

Shippers, 3PLs & receivers

When something goes wrong, everyone wants answers. Shared video and trip history help you explain what happened with facts—not guesswork or finger-pointing.

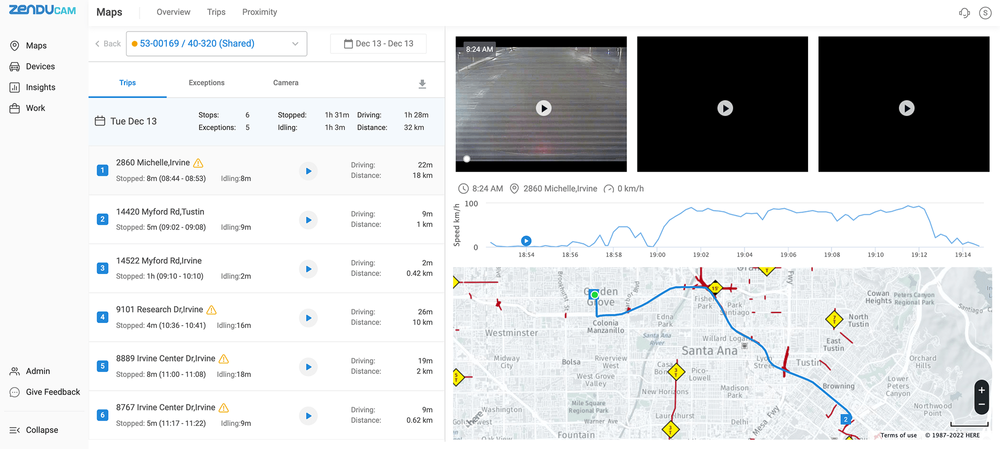

Dashcams, trailers & assets in one connected view.

CloudCam iQ ties driver behavior, camera views and asset tracking together so safety, ops and customer teams see the same thing from pickup to delivery.

- See what drivers, trailers and cargo were doing at every mile.

- Align video, GPS and temperature data into one story per load.

- Give customer service fast answers instead of “we’re still checking.”

Drivers, routes & events

- AI dashcams for collisions, complaints and harsh events.

- Multi-angle views around the tractor for cuts-in, merges and tight docks.

- Breadcrumb routes to reconstruct every leg of a trip in seconds.

Reefer trailers & remote assets

- Solar-powered trackers to follow trailers between yards and customers.

- Location and movement history for dropped trailers and pre-staged loads.

- Option to pair with temperature monitoring sensors for a complete cold chain view.

CloudCam iQ can integrate with existing telematics and routing platforms where appropriate, so your cold chain team doesn’t have to bounce between disconnected systems.

Hardware designed for long, multi-stop days.

Refrigerated operations mix long-haul lanes, local deliveries and staging time. Your cameras and trackers need to stay powered and recording through all of it.

- Keep cameras and trackers online through long hauls and yard time.

- Reduce gaps in footage around docks, hooks and high-risk moves.

- Know critical visibility is there before high-value loads roll.

Stable power & clean installs

Power distribution hardware tuned for fleet use helps keep dashcams and auxiliary cameras online without messy wiring or unreliable connections.

Coverage during transitions

Battery backup options help bridge brief power drops—during yard moves, hookups or when trucks are turned off but risk is still high around the trailer.

At-a-glance status

Remote views and dashboard indicators let supervisors check that cameras and trackers are online before high-priority loads leave the dock.

Temperature monitoring sensors available.

For fleets that want full cold chain visibility, CloudCam iQ can be paired with temperature monitoring sensors to capture live readings and alerts alongside video and GPS.

- See temperature trends next to route history and dock times.

- Get alerts when readings drift toward risk thresholds.

- Strengthen your story with video, GPS and temperature in one place.

How fleets use the add-on

- Monitor key reefer zones or sensitive cargo areas in real time.

- Align temperature alerts with door openings and dwell times.

- Export combined data for audits, customer reports and claims.

Flexible deployment

- Start with high-value lanes, customers or product types.

- Layer sensors onto existing CloudCam iQ camera/trackers.

- Scale as you standardize specs across your refrigerated network.

Moments when “we think” isn’t good enough.

When temperature-sensitive product is involved, customers and auditors expect clarity about what happened—not speculation. CloudCam iQ helps you answer the biggest questions quickly.

- Resolve “warm load” claims with clear, timestamped context.

- Show exactly where, when and how risk events unfolded.

- Turn investigations from days of back-and-forth into minutes.

Common scenarios we help you resolve

Use trip history to see dwell time at docks, routes taken, and how long the trailer sat at each stop, then align with your temperature system’s logs.

Match location and time to door-area camera views (where installed) so you can see when doors were open, where the truck was, and who was nearby.

Breadcrumbs and event markers show extra stops or unusual routing that may impact product risk or contract commitments.

Dashcam footage and route data provide a clear narrative for insurers and logistics partners when something happens en route.

How cold chain teams use CloudCam iQ

- Give customer service rapid access to route history and clips for specific loads.

- Support safety with real footage for coaching, not just metrics.

- Document on-time arrivals and dwell times at key customers or DCs.

- Align with temperature-monitoring data to tell a complete story.

- Highlight lanes or customers where risk and claims are highest.

Many fleets start by equipping high-value lanes or anchor customers, then roll out to the broader refrigerated network after they see results.

Service options built for temperature-sensitive freight.

When loads can’t be re-created easily, keeping your camera and tracking hardware online matters. Choose between standard warranty or the CloudCam iQ service program.

- Predictable support costs with the $5 per unit monthly program.

- Unlimited warranty while enrolled—ideal for critical refrigerated assets.

- Optional temperature monitoring sensors supported as you scale.

With service program

$5 per unit monthly

- Warranty and out-of-warranty repairs and replacements included.

- Unlimited warranty while enrolled in the program.

- Designed to keep critical video and tracking online without surprise bills.

Without service program

- Standard 3-year warranty on covered hardware only.

- Customer is responsible for labor (CloudCam iQ can provide labor separately).

- Out-of-warranty issues are not covered.

We’ll help you decide which tractors, trailers and lanes should enroll based on risk, volume and customer expectations.

Get a cold chain demo & quote.

Share how many refrigerated trucks and trailers you run, your key lanes, and your biggest concerns. We’ll follow up with a tailored demo and pricing options.

- Short conversation focused on your refrigerated network.

- Live walkthrough of cameras, trackers and temperature-sensor options.

- Clear pricing, including the $5 per unit monthly service program.

We typically respond within one business day. No spam, no hard-sell—just a focused conversation about how CloudCam iQ can tighten control over your cold chain.

- • Ideal for fleets with 5+ active refrigerated units.

- • Options for regional, long-haul and local delivery.

- • Service program available at $5 per unit monthly.

Request a demo or quote

Tell us about your refrigerated fleet and we’ll reach out with next steps.

Cold chain questions we hear most.

Logistics leaders, safety teams and quality managers tend to ask similar questions when they first look at combining video, tracking and temperature data.

- Clarify how CloudCam iQ fits with your current temperature systems.

- Set expectations around rollout, fleet size and integrations.

- Understand how other refrigerated fleets use the platform day to day.

Does CloudCam iQ replace our temperature system?

No. CloudCam iQ focuses on video, tracking and events. We can align with your existing temperature-monitoring data—or optional sensors—to help you tell a complete story for each load.

Can we see when and where doors were opened?

With cameras positioned at doors or docks and aligned timestamps, your team can review exactly where the vehicle was and what was happening around the trailer.

Will hardware hold up to long-haul and mixed routes?

We use commercial-grade components and mounting designed for 24/7 fleet use—linehaul, regional and local delivery included.

How fast can we start?

Many fleets begin with a focused pilot on key lanes or customers, then expand as they see improvements in claims handling and customer confidence.

What sizes of fleet do you support?

From smaller regional refrigerated fleets to larger multi-terminal operations. We’ll size hardware, data and service to your network.

Where do demos happen?

Demos are typically virtual. We’ll walk your team through real screens and workflows, tuned to your cold chain operations and top priorities.

Ready to tighten control over every cold mile?

Share your network, lanes and mix of tractors and trailers. We’ll walk through a CloudCam iQ demo tuned to cold chain operations and the $5 per unit monthly service option.

Book a Cold Chain DemoPrefer to talk first? Call 732-327-4327 or email sales@cloudcamiq.com.